Benefits of investing in a Warehouse Management System

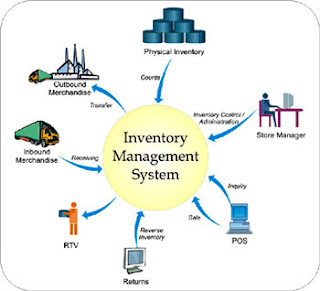

Innovative technology and modern distribution techniques are used worldwide, backed by warehouse management systems providing warehouse management solutions for many organizations. From ineffective inventory management to poor customer service, a Warehouse Management System (WMS) proves to be a resourceful step towards building a better business. Warehouse management systems are software applications that support day-to-day operations in warehouses. WMS programs enable the centralized management of tracking inventory levels and locating stocks to fix common challenges faced by distribution companies. Here we list a few benefits of investing in a WMS for your company. ● An efficient warehouse management system improves inventory management by creating faster inventory turnover. It limits inventory movement and improves record accuracy reducing the need for safety stock. It reduces the risks of having too much stock or situations where you may run out of stock. ● War